Your Muesli Production with Swarm

From Raw Materials to Market Shelves, Ensure Quality Every Step of the Way

From Raw Materials to Market Shelves, Ensure Quality Every Step of the Way

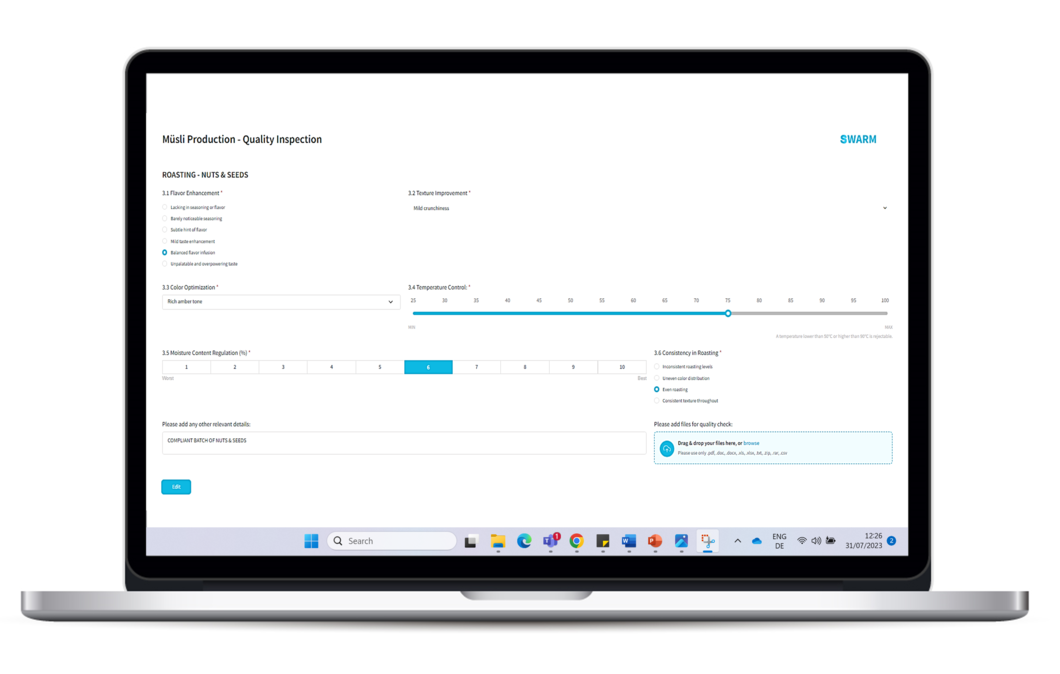

The data collection provided by Swarm enables efficient data capture and entry by quality technicians, providing valuable information for data analysts, quality engineers, and laboratory analysts in a Muesli manufacturing facility. This feature allows seamless collaboration among these personas to maintain quality standards, optimize processes, and drive product improvement.

From the sourcing of the raw materials, their processing and mixture, up to the packaging stage, and their distribution to the market shelves, Swarm is an intelligent form as a service that can track and monitor the quality of the product through all its stages. It allows people from the manufacturing facility to send data in real time from their own devices to the back-office teams. It can also be integrated as desired into central ERP systems such as SAP.

In this article, we focus on the grain processing & roasting stages to describe how Swarm can support the people involved and leverage the whole process with offered functionalities.

|

Grain Selection |

Swarm includes options for quality technicians or data analysts to choose from a predefined list or manually input grain varieties based on the recipe or product requirements: size and shape, nutritional composition, texture, aroma, and taste. |

| Cleaning and Sorting | Quality technicians enter information in Swarm about the removal of impurities, foreign materials, or defective grains, ensuring proper quality control. |

| Moisture Content Monitoring | Swarm can integrate with moisture sensing devices or allow manual entry of moisture measurements for grains. Quality technicians can input the moisture content during the processing stage, ensuring adherence to specified ranges. |

| Milling Parameters | The application provides fields to input the milling parameters for grains. Quality technicians can specify factors such as milling speed, duration, and particle size to achieve the desired consistency and texture. |

The quality engineer ensures proper cleaning, sorting, and milling techniques are followed. They receive the data provided by the technician in Swarm and review the recorded data while monitoring parameters. After this step, the quality engineer performs the usual activity of creating the inspection plan, conducting it, and also continuing the activity with the help of SAP Quality Management functionalities.

In conclusion, quality management and all its stages continue to play a vital role in optimal business operations. To maintain high product quality and meet customer expectations, companies must benefit from the latest technologies and software and use them for tracking production. Swarm is a tool that can digitalize your business operations and optimize quality management activity.

Ready to revolutionize your Muesli production with Swarm? Contact our experts today and embark on a journey toward unmatched quality and efficiency.

Contact Our Experts