In today's rapidly evolving world, sustainability has become a critical consideration for businesses across various industries. The automotive sector, in particular, faces the challenge of measuring and managing the carbon footprint of its products throughout their entire lifecycle, from the initial production stages to the end product. This blog post explores how SAP Sustainability Footprint Management (SFM) can address this challenge by offering industry-specific solutions tailored to the automotive industry.

The process of calculating the cradle-to-gate carbon footprint of automotive products involves three key stages:

SAP SFM provides a comprehensive framework for mapping and analyzing each of these stages in detail.

1) Purchase of Raw Materials or Semi-finished Products

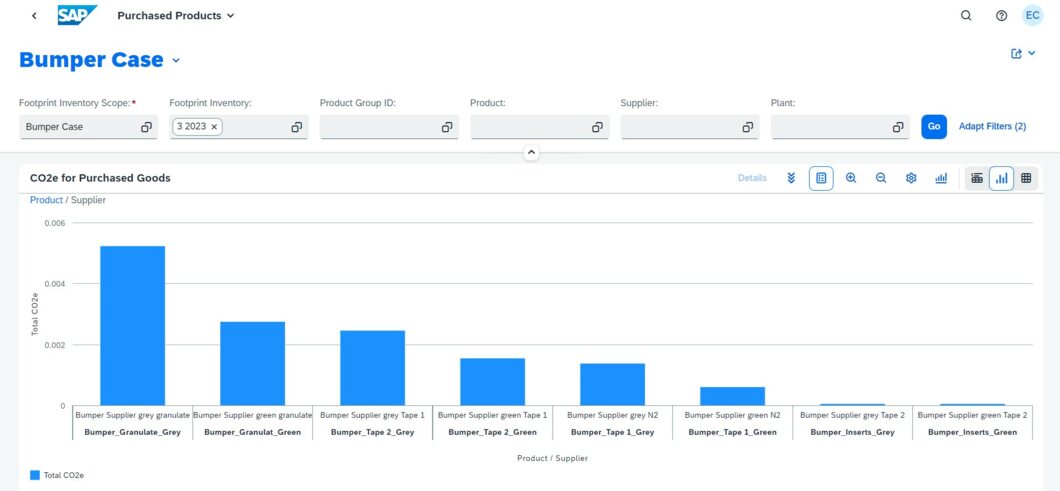

Let's delve into each stage and see how SAP SFM facilitates carbon footprint management. Firstly, purchased products, such as inserts, granulate, and tape, can be configured within SFM and assigned to their respective suppliers. Furthermore, emission factors specific to each product can be created, allowing for the evaluation and comparison of product footprints across different suppliers. Fig. 1 visually represents the product footprints of various products and suppliers, providing a comprehensive overview.

2) Transportation of Materials to the Production Site

Moving on to the transportation stage, SAP SFM enables the calculation of transport emissions based on supplier and production facility locations. In cases where specific transport information is unavailable, SFM leverages its extensive database of train stations, airports, ports, and associated emission factors from GLEC (Global Logistics Emissions Council) to generate suitable transport routes for each product. This ensures accurate calculation of transport-related emissions.

3) Production of the Final Product

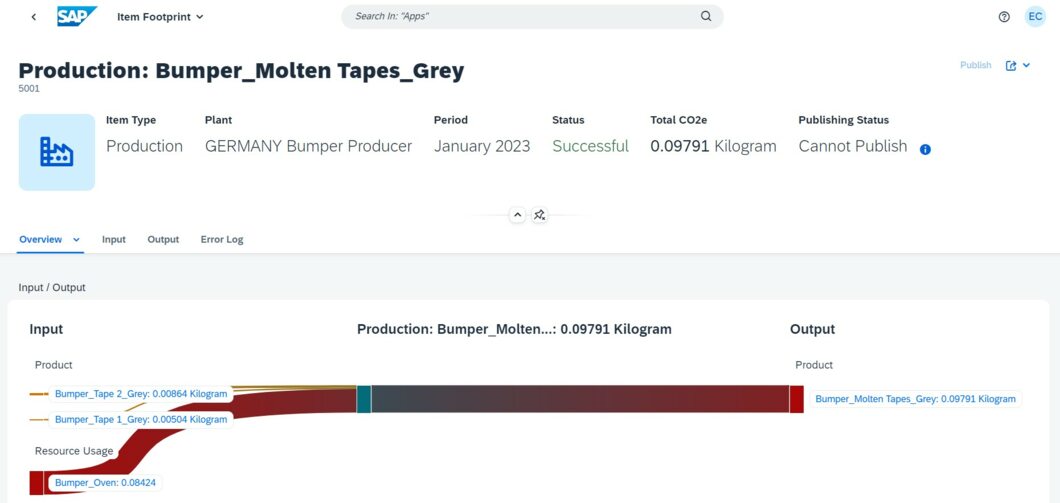

When it comes to product construction, the purchased parts undergo various processing steps across different plants. SAP SFM allows for the plant-specific mapping of these process flows, enabling the evaluation of the CO2 intensity at each step. By configuring all relevant plants, their activities, and the energy types utilized, the CO2 emissions associated with each process step can be precisely measured. Fig. 2 illustrates an example where purchased tapes are fused using an oven, showcasing the respective CO2 emissions from both the tapes and the heating process.

By leveraging SAP SFM, businesses in the automotive industry can gain full transparency into the cradle-to-gate emissions accumulated throughout the production lifecycle. With accurate information on CO2 consumption at each step, companies can make informed decisions to optimize their operations and minimize their environmental impact. SAP SFM empowers automotive businesses to embrace sustainability, meet regulatory requirements, and contribute to a greener future.

Stay connected for more industry-specific use cases and insights on how SAP SFM can revolutionize sustainability management across diverse sectors.

Are you interested in learning more about the Emissions Calculator?

Please get in touch with one of our experts, who would love to hear from you.